26 Feb 2026

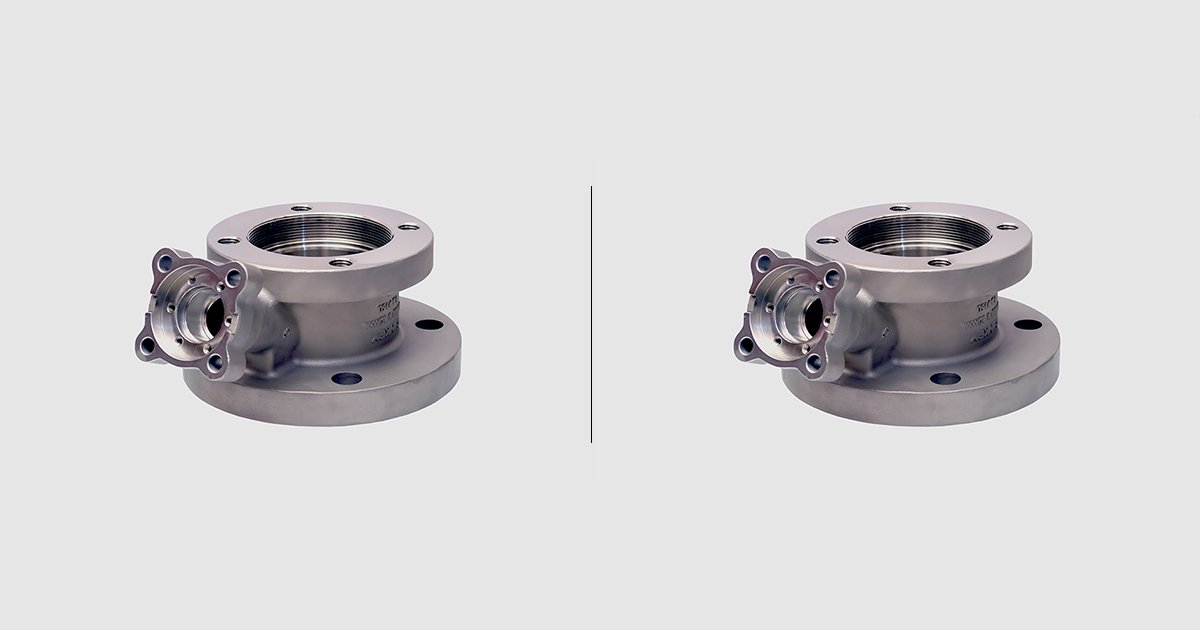

Sourcing engineered components like investment castings and component suppliers for food processing, earth moving, oil and gas, medical and general engineering is a huge challenge. It becomes even more challenging when the components from two or more manufacturers look similar. Many times, two different products look similar visually but there are differences you can’t find through your naked eyes.

What defines the difference in two similar looking components?

The investment casting process is employed similarly across the globe. When it comes to differentiating between Investment Casting companies, the stand-out factors are testing facilities at manufacturing units, consistent quality and capacity to manage uncontrolled parameters.

Most of the manufacturers outsource quality testing from other service providers. Not having a testing facility at the manufacturing unit leads to delay in the manufacturing process and defects in cast components manufactured. One of the other issues industries worldwide face is that they don’t get consistent quality products supplied in each lot. You may have faced situations like when the samples provided are perfect but consignments delivered are not up to the mark. For many OEMs it’s extremely challenging to maintain consistency in Investment Casting parts. Casting companies with a strictly controlled and monitored environment can manufacture components with consistent quality. Tolerance factor, surface finish, lower dimensional accuracy and cost are some uncontrolled parameters which some OEMs have ability to control.

Featured facilities at Austin Alloy Cast, which makes their investment casting components of world-class quality.

Austin Alloy Cast Pvt. Ltd. is leading investment casting manufacturers in India with capabilities to supply their products in Europe, North America, APAC & South America. Following featured facilities at Austin Alloy Cast Pvt. Ltd. make their investment casting components of world class quality.

Non-destructive Testing:

○ Dye Penetrant Testing

○ Magnetic Particle Inspection

○ Radiography Testing

○ Ultrasonic Testing

○ CMM

In-house NDT testing facilities like Radiography makes us less dependent on outside vendors for our testing requirements and help achieve our motto of Unmatched Customer Service by Consistent Quality and Exceptional Delivery Performance.

Skilled workers:

250+ skilled workers with years of experience and a management team with a lifetime of experience in the Investment Castings manufacturing.

Strictly controlled and monitored environment at different stages of the process including parameter tracking and control at Wax Injection, Coating & Drying, De-Waxing, Melting & Pouring, Heat Treatment, Fettling and Quality Inspection.

To have a glimpse at our world class facility and products, visit us at www.austinalloycast.com.

For any queries or details contact us at info@austinalloycast.com.